Kabwet Clinic - Reflections

Wednesday, February 13, 2013 at 3:49PM

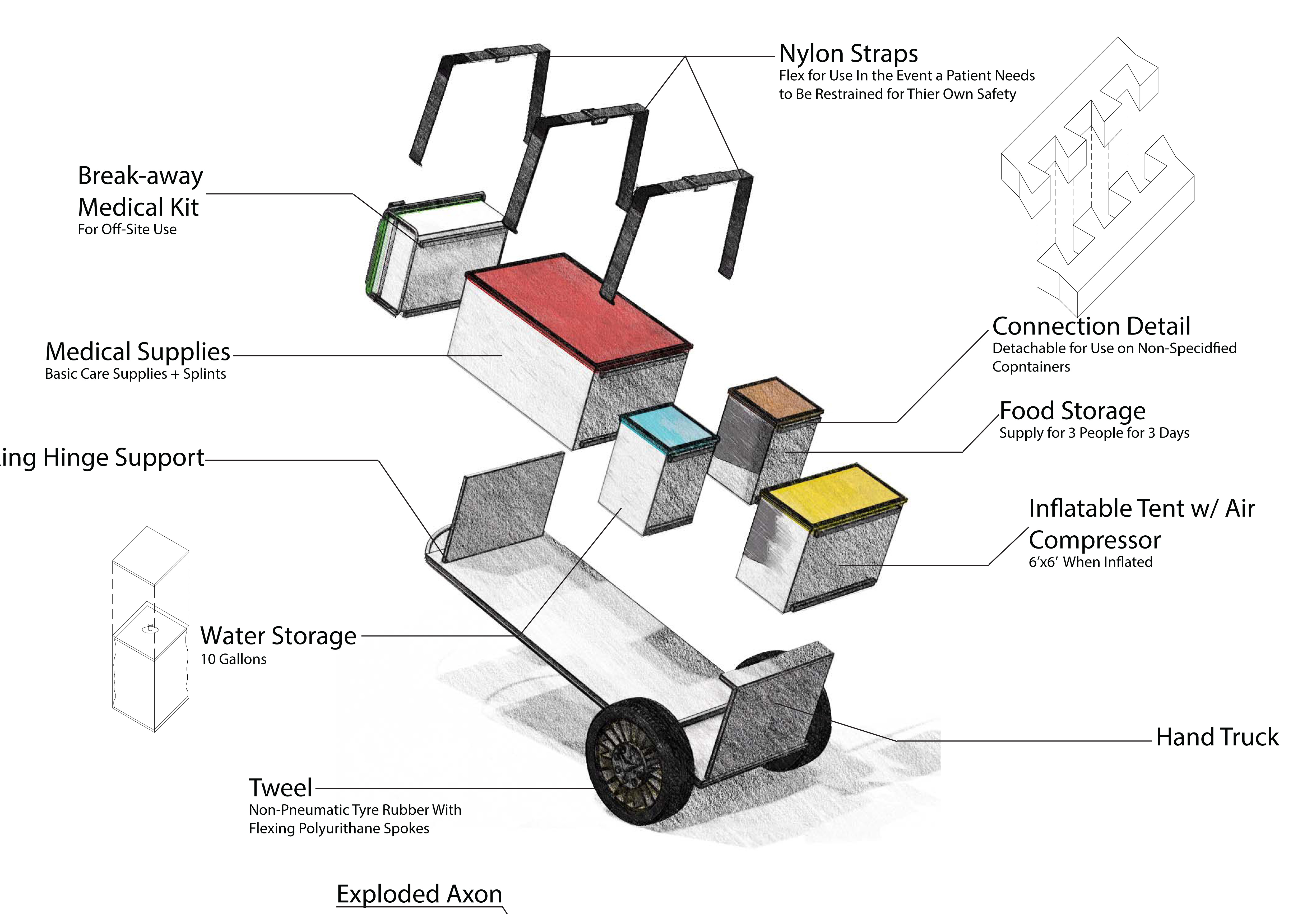

Wednesday, February 13, 2013 at 3:49PM This project, the Kabwet Clinic, is the design of a mobile medical unit meant to be used in rural locations by Haitians for Haitians. The unit would be stored in the city hospitals and deployed to remote locations on a systematic, daily basis in order to help release the existing pressure of overwhelming medical need in those areas. The design for the Kabwet Clinic is easily sustainable in such an area due to its ability to travel through diverse terrains by a variety of vehicles, and existing of components that can be replaced by local materials. Its design maximizes its lifespan and functionality. The key to the success of the Kabwet Clinic is its implementation into the Hatian culture and continued use by its population.

Ultimately, I feel as though this project is a success to its purpose. I would have liked to have more time to show in more detail the overall lifecycle of the cart specifically since we designed it so that it could be used for purposes other than the clinic. We did this for every aspect of the project but it was not shown as strongly as I would have liked in the presentation. I am very proud of the illustration that we did use, however. I believe they communicate what we meant the to communicate.

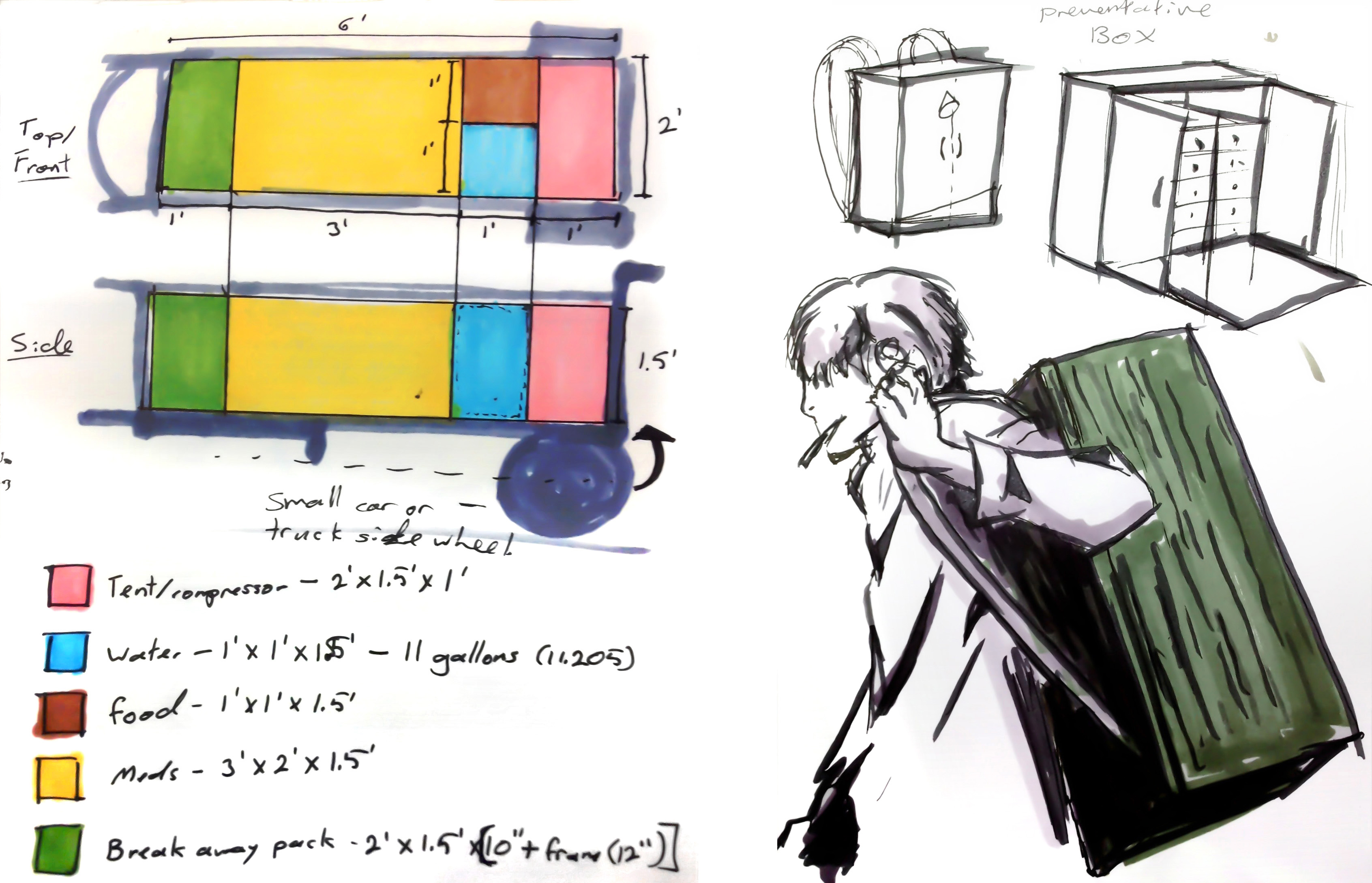

The cart was probably what changed the most throughout the process. Our first iteration of its design was much more complicated, specifying an extra set of wheels, a hand crank and a far-too-unrealistic hinge system. That we were able to siplify the transformation to a single hinging panel is a testament to the power of collaboration. One of the things that most affected the design process was the change in type of medical treatment it was to provide. Much of the equipment we thought would be necessary in our early iteration was dropped in favor of carrying more of the basic care essentials - a decision that proved to be most advantageous as it lead to the possibility of a modular, multipurpose storage system.

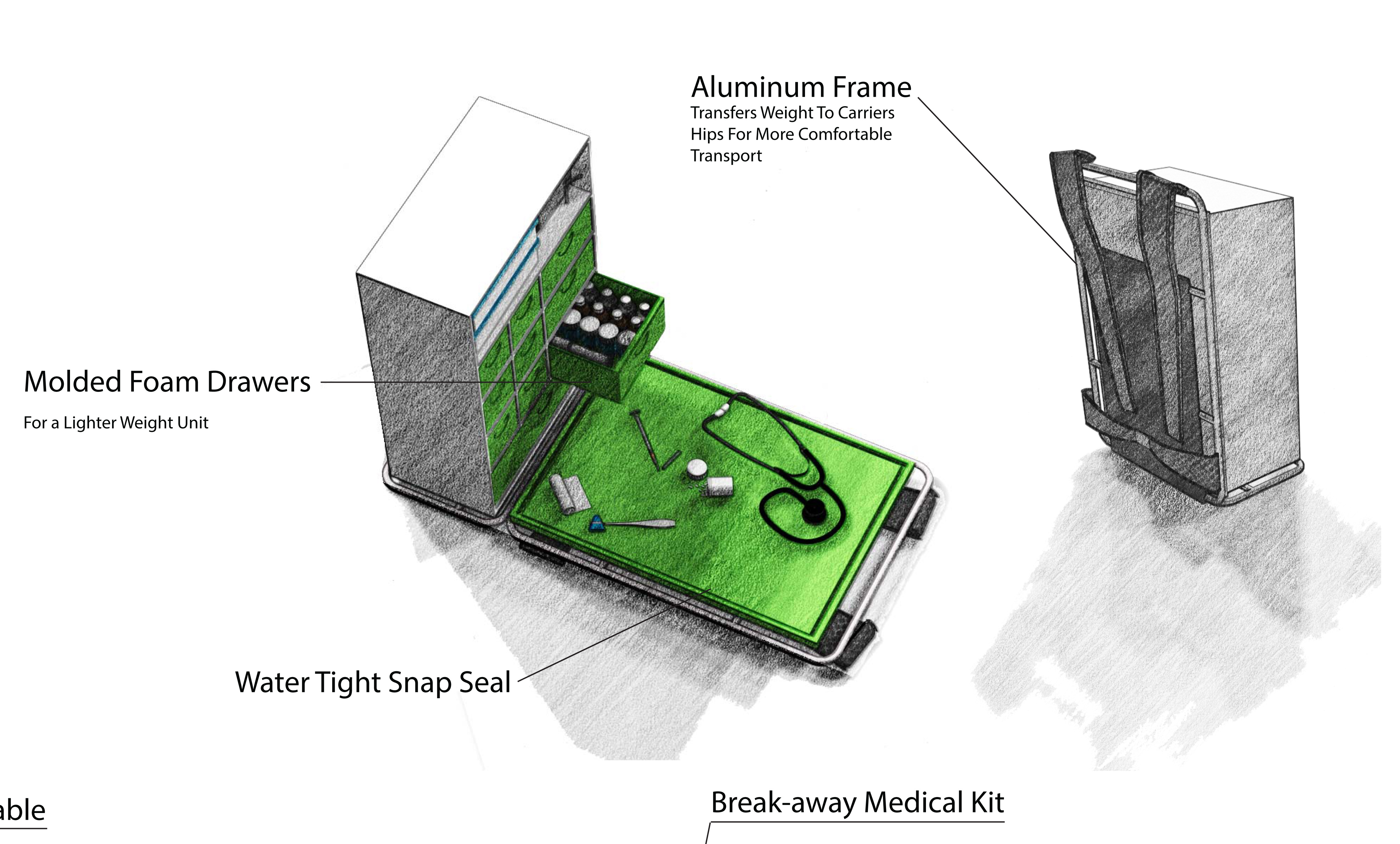

If we had more time to work on this design I would hope to rework the modular system to consist, instead of snap-seal plastic water-tight containers, of hefty wove baskets with a ridged lid and frame so that they could still be used as seats and work surfaces but could be manufactured locally. In order to make them water-tight I could specify an inner plastic layer that would serve as a sort of water skin and surround the contents of the boxes.

Mitzi Coker

Mitzi Coker

I really like the design of the Kabwet Clinic. The efficient use of space and the carts ability to be transformed into an examination table is a great idea. The over-all design is pleasing, compact, and well thought out. I think your thoughts on having the containers (baskets) woven by locals is a really good idea. Everything that can be manufactured locally is great for the economy and also less expensive due to shipping costs and transportation issues. Just curious...How did you come up with the name of the clinic? Did it have to do with the tires you used on the cart?

Mitzi Coker

Stephen Sawyer

Stephen Sawyer

I really like this medical pack. It would provide an ability to carry a lot of material, require little to no maintenance, detach medical supplies for easy access and availability, and also provide the user with an easy way to rest removing the weight from the shoulders during transport.